Extended Producer Responsibility

With rising awareness and evolving regulations, navigating packaging EPR across global supply chains is complex—Specright helps you understand requirements, design for recyclability, and meet compliance proactively.

Why EPR Matters Now

There are over 130 EPR laws across 33 U.S. states and 500+ schemes globally, with more on the way.

Extended Producer Responsibility (EPR) shifts responsibility for end-of-life waste management — from recycling to disposal — away from municipalities and consumers back to the producers (brands, manufacturers, importers). The objective is to drive sustainable product design and support a circular economy.

Companies must not only comply with these new regulations but also collect, manage, and disclose detailed data on materials, packaging volumes, lifecycle impacts, and end-of-life outcomes. Failure to comply can lead to penalties, reputational risk, and operational disruption.

Streamlining EPR Reporting through Collaboration

Specright created the Sustainable Packaging Data Council (SPDC), a collective uniting leading brands, retailers, technology partners, nonprofits, and academia with one shared mission: to harmonize data and accelerate packaging sustainability.

As Extended Producer Responsibility (EPR) legislation rapidly expands across the United States, alongside other sustainability regulations such as the EU’s PPWR, the SPDC is helping organizations prepare by developing a standardized U.S. EPR data requirements framework, with PPWR templates forthcoming.

Built on cross-industry collaboration, this guidance template clearly identifies what data is needed from teams for compliance, streamlined supplier collaboration, and future preparation when it comes to sustainability reporting.

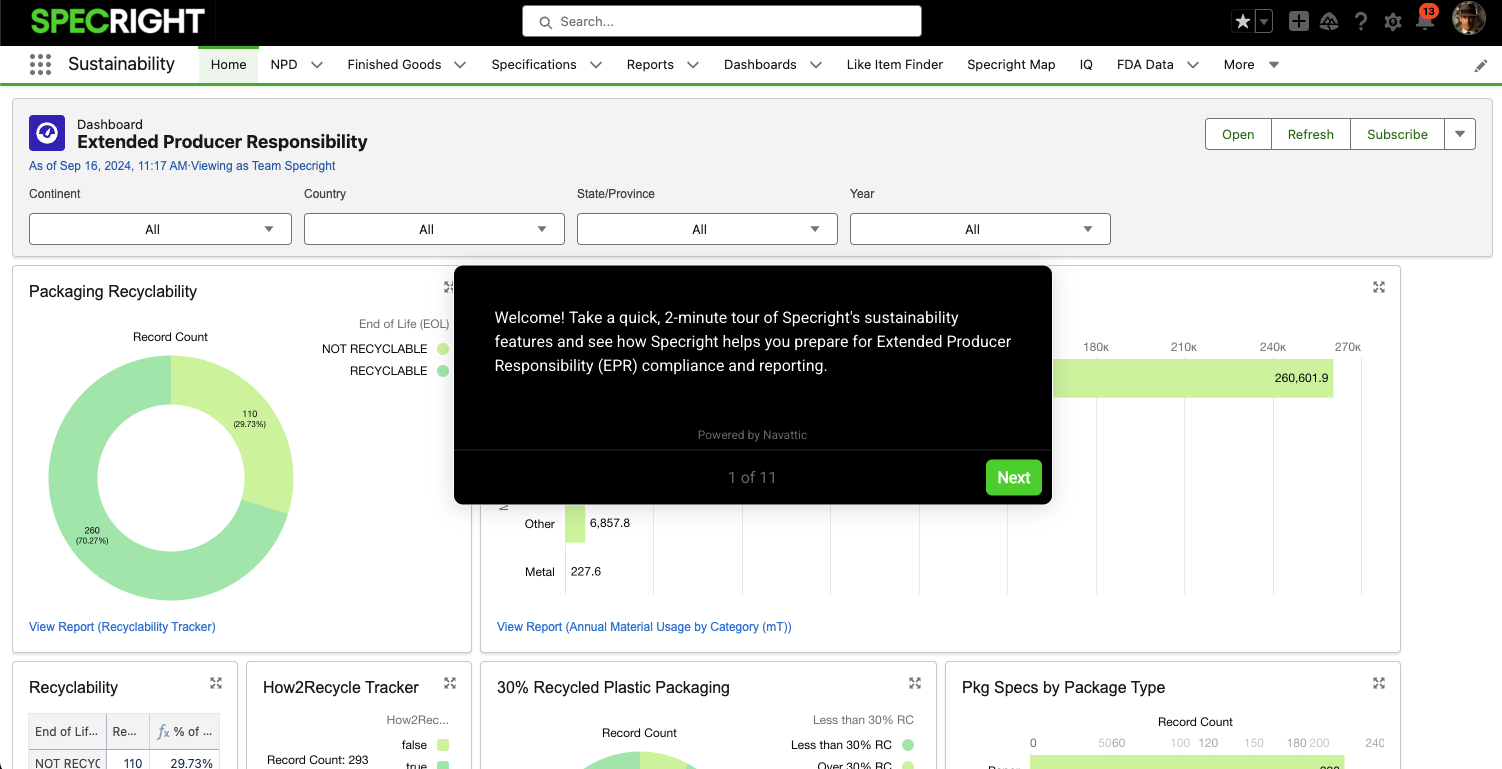

EPR in Action

With Specright, you can ensure critical data requirements are being tracked and validated, so as requirements grow, your compliance can easily scale.

Specright + Lorax: EPR Compliance Starts with Data

As the leader in Specification Management, Specright believes strongly in partnering with other industry leaders. That’s why we have a strategic partnership with Lorax EPI, the leader in EPR reporting. Our partnership aims to simplify sustainability reporting, combining world-class data management with deep regulatory expertise.

Unilever Prestige Implements Specright Across Enterprise

Unilever Prestige partnered with Specright on a centralized Specification Data Management (SDM) platform system to streamline its fragmented packaging and raw material specifications across 10 luxury beauty brands. The phased implementation across its brands focused on data standardization, regulatory compliance, and sustainability tracking, resulting in significant efficiency improvements and cost savings.