In recent years the term and software category “specification management” has gained traction rapidly among industry trends, even being recognized by industry leaders like Gartner. It’s not just something companies know they need to do – better manage specification data – it’s something companies must do to maintain any competitive edge in today’s challenging environment.

In response to this increased traction, the technologies, and innovations that have emerged in response have grown exponentially as well.

From cloud-based software to artificial intelligence (AI) and machine learning (ML), companies around the globe are looking for the next best way to manage their specification data. Existing systems, like Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) solutions, aren’t making the cut when companies need to leverage the DNA-level data of their products and packaging. And, on top of cost optimization initiatives and supply chain complexity, companies are being forced to rethink how they manage data due to regulatory pressures, like the UK Plastics Tax and Extended Producer Responsibility.

Current State of Specification Management

With the rise of complex supply chains, increased SKUs, and sustainability pressures, companies are facing many challenges related to the functionality of their business models.

And a lot of this functionality is related to setbacks stemming from poor specification management.

As companies shift and expand, developing new product lines and adapting to the surrounding environments, more data is compiled, and data that is crucial to making these changes successful.

In the most recent State of Specification Management Survey, it was clear that data is increasing, yet the solutions to managing this increase in specifications are still inadequate.

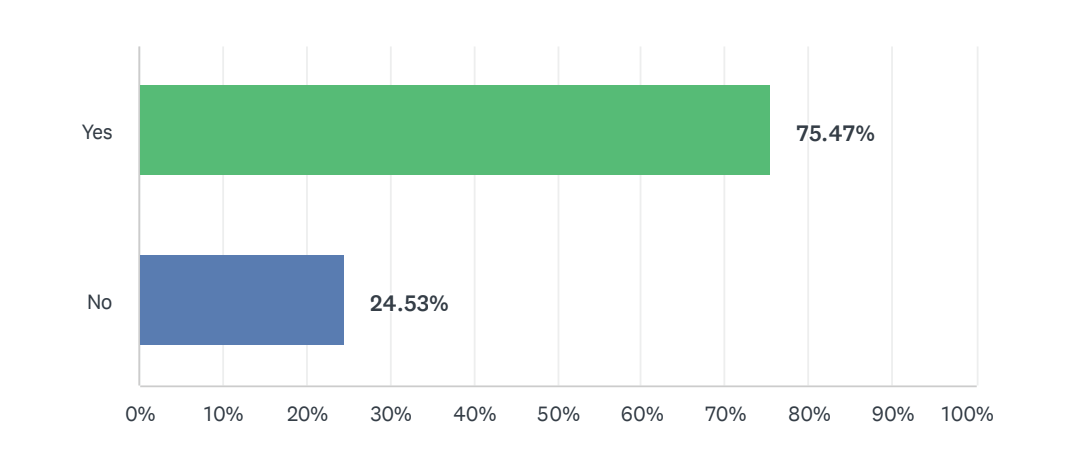

When respondents were asked if they saw a need for better specification management in their organizations 75% responded yes.

Despite organizations knowing they need better data management tools for their products and packaging, there is still a lack of action.

But with the constant evolution of consumer demands and expanded product portfolios, having the adequate tools needed to manage specifications and product lifecycles is key.

But despite the growing discussion related to the value of specification data management, many companies are still not familiar with its best practices.

As seen in Figure 2., below, from the State of Specification survey, companies continue to use shared drives and email to manage specification data. The reality is adding PDF documents to shared drives or sending them via email is still a static approach to data management. This opens your business up to risk by leveraging potentially outdated versions of data and miscommunication. Managing data in PDFs also makes it difficult to run reports or search through specifications quickly.

Although with advancements in purpose-built technology and a shift towards digital specification management software, more companies are facing these challenges head-on in order to meet business needs.

If you want to learn more about the State of Specification Management, register for our upcoming panel-discussion webinar on the survey results, best practices, and key takeaways your company can leverage today.

Emerging Trends and Technologies in Specification Management

With the rise of robotics, AI and ML, and advanced cloud-based technologies, companies in every sector are discovering new ways to improve their business models and ensure their workforce is focused on innovation vs. data chasing.

And beyond just being trendy, these emerging innovations are giving companies the opportunity to stay ahead of their competitors.

AI and Machine Learning

It’s very likely that regardless of the industry you work in you have heard of artificial intelligence, or AI.

But if not, in its simplest form, AI refers to the use of computer systems and machines to perform tasks that would typically require humans.

Machine learning is also on the rise which is a subfield of AI, focused on developing algorithms and models that enable computers to learn and make predictions or decisions without being explicitly coded. Meaning that as more humans input information and data into the systems they learn and improve over time.

To some, the idea of replacing human tasks with computers and machines is an unsettling one, but the reality is when used effectively they are a tool for cost optimization and efficiency – especially in the world of specification data management.

Leveraging artificial intelligence and machine learning takes digital transformation to the next level, allowing companies to use automation for certain aspects of their specification data.

When it comes to analyzing large volumes of data and identifying patterns, or making recommendations for specification optimization and compliance checks using automation and machine learning can help save the valuable time of your team members, and in return drive cost savings.

Although at the end of the day, even with the most advanced AI and machines if the data being inputted into these systems isn’t accurate then all value is lost.

Data is the foundation for creating meaningful AI insights. It is important to remember that AI systems cannot give you and your team quality outputs if accurate data is not fed into these systems, to begin with.

And unfortunately for most organizations, inconsistent data and siloed teams still drive business operations. In return any AI that is implemented cannot do its job correctly in the first place – further driving inaccurate data coming out of systems.

Even if your company is leveraging AI/ML technology, if you are not collecting the right data, recommendations, and analysis will be based on incorrect data – and therefore unhelpful.

That is why taking a spec-first approach to developing a strong data foundation is so important when utilizing these tools and technology and shifting business methodologies.

Cloud-Based Technologies

Another trend that has experienced massive growth in recent years related to specification management is cloud-based technologies, and this growth just keeps rising.

In a case study done by the Harvard Business Review, a technology startup stated that “The product, which might normally take six months to a year to create, was finished in 10 weeks, thanks to accelerated testing, and direct communication with the customer about needs and specifications during design and construction.”

And the reality is all this wouldn’t have been possible in the world of spreadsheets and Excel – it’s all enabled by the cloud.

More than ever, companies are being forced to leverage data to quickly address supply chain complexities, report on sustainability, respond to consumer demands, and keep up with ever-changing trends. The only way to tackle these challenges is through a strong data foundation.

.png)

Braga Fresh dealt with this firsthand and used Specright’s cloud-based software as a driving solution.

As Richard Warsaw, VP of Food Safety and Quality, at Braga Fresh stated, “Specright was the obvious choice for Braga Fresh to consolidate and digitize our specification information and start thinking about specifications in more than two dimensions. This program will accelerate our R&D pipeline and drive operational efficiencies through immediate access to accurate information for every department in our organization.”

With Specright’s implementation and a spec-first approach, Richard and his team were able to see progress and transform their business within a short 8-week period. Learn more about Specright’s Activation Packages here.

With cloud-based software, companies are enabled to implement real-time collaboration and information sharing, which is especially important for geographically dispersed teams.

And this information is highly valuable when it comes to specification management because it allows all stakeholders (internal, customers, and suppliers) to access and work on specifications simultaneously – all while tracking changes and ensuring consistent information both on-premises and in the cloud.

When it comes to product development having specifications related to raw materials and other product information in a cloud-based technology makes the process much more seamless.

.webp)

Each year, Ocean Mist Farms, the largest grower of fresh artichokes in the United States, receives hundreds of requests for new products from their customers.

However, prior to the implementation of Specright, these requests were difficult for the product development team to process, manage, and bring to market due to legacy processes and systems.

In Specright, Ocean Mist Farms was able to centralize and digitize product development requests, track progress over time, perform break-even analysis, and ultimately ship new products. To read more about Ocean Mist’s success with product development and cloud-based systems read the case study.

Specification management systems such as Specrigh’s patented, Specification Data Management Platform, allow for more flexibility and connectedness of all team members, providing one source of truth for product specifications, packaging specifications, and specification documents, like BOMs and COAs.

Specright’s software is built off of templates that allow for consistency of data and a mutual understanding of inputs from all team members – driving more efficient approvals and visibility across teams.

The networks of suppliers and retailers are growing for most businesses making the need to share and access unified data across the globe a must.

And additionally, it allows for live changes that reduce the expenses and time wasted by incorrect data, simplifying the overall management process.

Supply Chain Optimization and Visibility

The COVID-19 pandemic exposed the vulnerabilities of supply chains and highlighted the critical importance of having accurate and up-to-date data.

And at the end of the day, it revealed to many companies that unfortunately they were lacking easy access to this critical data.

The absence of critical data about demand patterns, inventory levels, and supply availability, caused the inadaptability of many companies in a time of unexpected disruption.

As we have seen in recent years supply chains are growing and only becoming more complex which is why having visibility and adequate specification data is even more important.

In a recent webinar, with Paul Gray, Director of Quality at Central Garden and Pet he spoke on the value of using Specright to drive visibility,

“With Specright we have the ability to see all the products we’re working on for just a subset or a business unit. We can drill down into the data which gives us a lot of visibility… Everyone can go in and see where their projects are, who’s working on them, what the impact is, what the timing is, and what’s on track. What you’ll find is that with the power spec, right? It’s not only in the specifications it’s in the ability to use that data in the system to drive improvements instead of just having data in the system that you can’t use.”

End-to-end supply chain visibility and clear insight into workflows allow companies the ability to track and monitor products, materials, and information necessary in executing the various levels of their company.

Additionally, as a result of various changing environments, regulatory crackdowns are only becoming more intense, making the need for data in order to adapt to these changes quickly, a must.

With the right tools, companies can begin to house the data they need to enable everyone in their networks to have visibility into all elements of their company’s supply chain.

Future of Specification Management

Between the expansion of AI and automation, the growth of cloud-based technologies, and a better understanding of global supply chains, the future of specification management is strong.

Specification data management is no longer a nice to have for companies, it’s a must and is a globally recognized term in every industry.

Emerging technologies and future advancements related to products and packaging are more than exciting but ultimately what is driving these breakthroughs is the data behind them.

Data is the driving force behind these sophisticated inventions which is why at the end of the day data at the DNA level is the future of specification management.

No matter what industry you’re in, these changes will play a role in how your business can operate and stay competitive. That is why taking proactive steps to adapt to the shifting environments is so valuable.

Companies willing to lean into these changes will be able to stay ahead of competitors and remain industry leaders.

And here at Specright, we want to help you do just that.

As the industry’s leading cloud-based specification data management software our team here at Specright is leading companies into the future of specification management.

To learn more about Specright and how it can help your team stay up to date with the latest industry trends, request a demo.

And, don’t forget to join us for the upcoming State of Specification Management Webinar on July 25th. You can register here.

Explore More Blogs

Get Started

With Specright’s Solution Suite, you can digitize, centralize, and link your specification data to drive efficiencies, intelligence, traceability, and collaboration within your organization and across your supply chain network.