Food and Beverage Specification Management

With accurate specification data, you can accelerate new product development while ensuring quality and food safety. And with a single source of truth for data, you can easily collaborate across teams and supply chain partners.

Why Food & Bev Companies Use Specright

Break down data silos across your organization to:

- Accelerate Speed to Market: Consumers demand product variety. With Specright, keeping track of specs in one place helps you go faster.

- Ensure Food Safety & Quality: Recalls often occur due to a lack of accurate data and ability to track changes. With Specright, ensure the spec is right every time.

- Streamline Reporting & Compliance: Whether it’s sustainability reporting or FSMA compliance, managing your products at the spec-level allows for easy and accurate reporting.

Specright Features For Food & Beverage

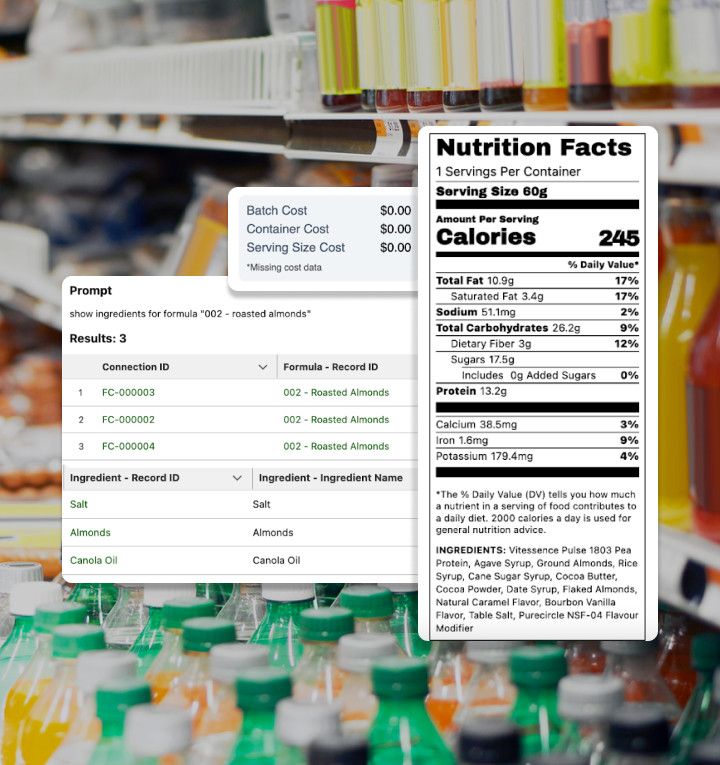

Data Management for Products, Packaging & BOMs

- Manage specification data including raw materials, ingredients, formulas, and bill of materials in a single source of truth. Say goodbye to outdated excel spreadsheets, shared drives and legacy systems.

- By linking specifications together, you can see where components are used across your portfolio. For example, easily identify all products that contain gluten or that use a specific type of packaging.

- Ensure everyone on your team is aware of product changes at every level to ensure quality and food safety. For example, easily see when a formulation change requires a packaging and labeling revision.

Supplier Collaboration Portal and Workflows

- Suppliers, co-manufacturers, and plants need to work off accurate data to make the product right, every time. Easily share data across your internal departments and external partners.

- Ability to collaborate on spec changes across suppliers using workflows and approvals.

- Enhanced visibility: Oftentimes your suppliers own granular spec data related to your products. With our supplier portal, they can easily add and enrich the data you need for sustainability reporting and compliance.

New Product Development & Product Life Cycle Management

- Easily manage and search through previous NPD projects to create an “innovation library.”

- Leverage new project requests, stage gates, workflows, and approvals to streamline product development and get products to market faster.

- Know where things stand with robust reporting and dashboards to provide visibility into what’s moving through your pipeline and what’s stuck.

Bob Evans Farms Transforms PLM Process and Product Innovation with Specright

For food & beverage companies like Bob Evans Farms that have multiple brands, getting quality products to market in record time is critical. A strong PLM and data management system is critical to meet changing consumer demands. With Specright’s Specification Data Management™ (SDM) platform and integrations with Genesis and 1WorldSync, Bob Evans Farms has a centralized single source of truth that helps them get new products to market faster and more efficiently.

Used By Leading Food & Beverage Companies

What Our Customers Say

“Specright’s Specification Data Management platform is a huge time and sanity saver. We now have one version of the truth that is far more reliable than the old way of doing things. It outperformed all the other systems we considered because it provided complete transparency down to the individual component level.”

Andy Kesler

Corporate Director, Supplier Food Safety & Compliance Systems, Taylor Farms

“The biggest value of Specright is its flexibility. I have a team member on Weston who’s constantly in the system, learning and figuring things out on his own. He’s able to add attributes and build relationships without needing to involve IT, which can be a lengthy process. That level of independence is a huge advantage.”

Johnathon Tran

Senior Engineering Manager, Tyson Foods

“Here’s where we stand with Specright today: we manage over 4,000 finished goods and 10,000 unique packaging and ingredient SKUs—each linked to five regions. We work with 850+ suppliers and track more than 20,000 supplier documents. We’re utilizing all core modules, including packaging, formulas, ingredients, finished goods, and quality, along with enhancements for regional costing.”

Chelsea Clark

Director of Sourcing, F&S Fresh Foods

Easily Integrate with Your Existing Systems

Specification Management For Food and Beverage Resources

Learn more about how to make amazing things using a spec-first approach.