SDM MODULE

Product Data Management

Connect teams and data for faster product development.

Accelerate time to market with clean, up-to-date product data shared across teams and suppliers.

Why Specright for Product Data

Accelerate Development with a Single Source of Truth

Bring all your product data together to cut rework and speed the path from concept to launch.

Collaborate Instantly—Inside and Outside Your Organization

Give teams and partners shared, up-to-date access so everyone stays aligned.

Eliminate Costly Mistakes with Built-In Accuracy Controls

Work confidently with automatic version control, robust validation, and a complete change history to ensure accurate data every time.

Trusted by Fortune 500, private label retail & challenger brands

Key Features

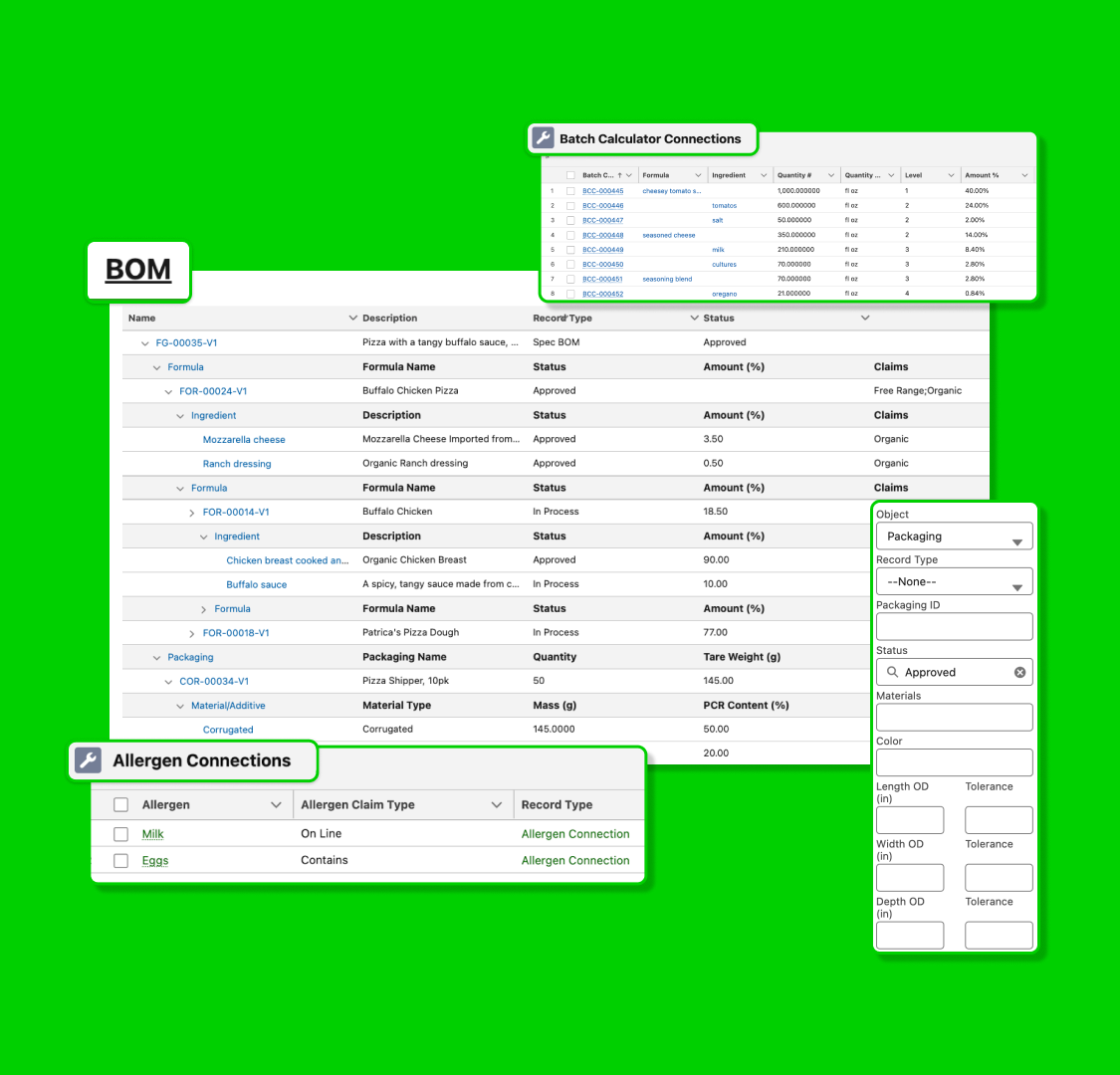

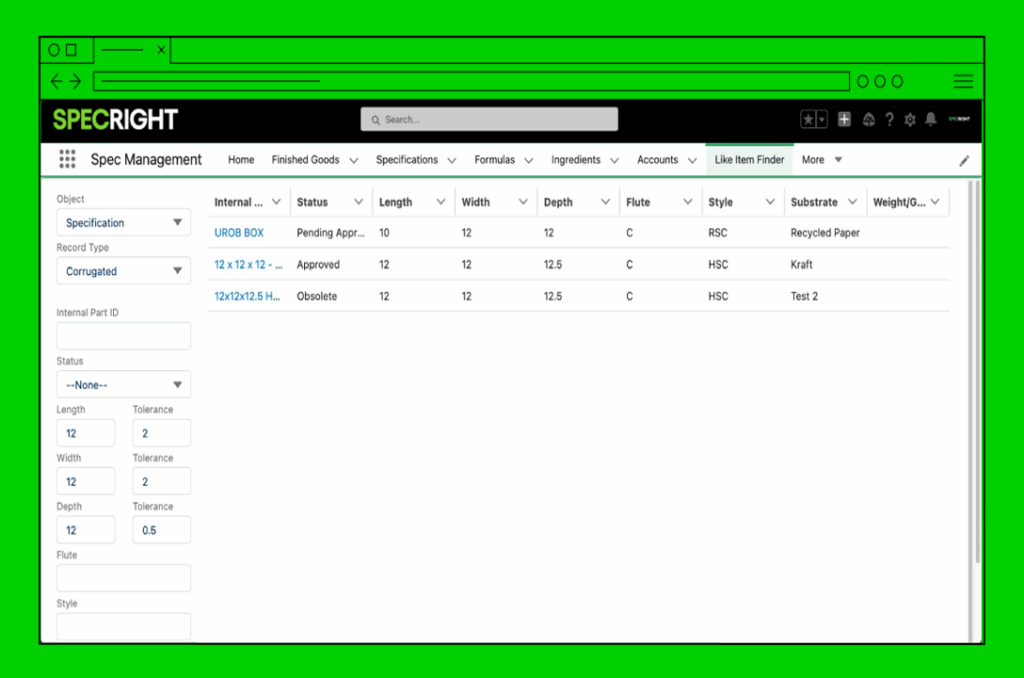

BOM Management (Product)

Connect formulas, ingredients, and components into a single source of truth—accelerating product development and ensuring manufacturing accuracy.

Validation & Process Blockers

Ensure data accuracy by checking entries against admin-defined rules—triggering error messages when inputs don’t meet the required standards before saving.

Batch Calculator

Calculate exact ingredient and sub-formula quantities by entering a batch size and unit—instantly scaling percentages to simplify formulation and production planning.

Claims Rollups

Track and manage product claims with built-in logic that rolls up data through ingredient, formula, and finished good hierarchies—ensuring accuracy and flexibility across product levels.

Allergen Rollups

Automatically roll up allergen data across ingredients, formulas, and finished goods—using standardized claims like “Contains” or “May Contain” to ensure accurate, end-to-end allergen tracking.

Process Steps for Formulas

(Coming Soon)

Enter step-by-step instructions, add brief descriptions, and include photos for each process step. Ensures clear, standardized documentation of processes, improving consistency, and execution across teams.

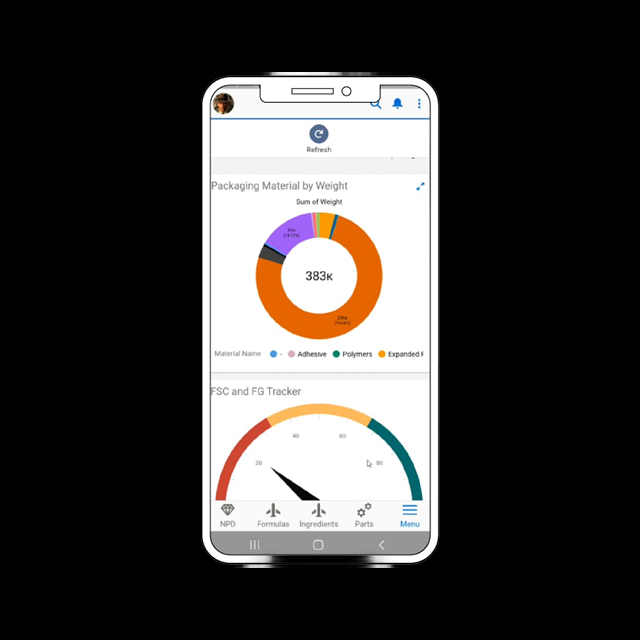

Impact Metrics

10%

Faster New Product Introduction

25%

Reduction of Non-Sustainable Materials

50%

Reduction in Duplicate Specs

10%

Reduction in SKU Overlap

What Product Experts Say

“I no longer have to search

for information and validate the source—I grab

the information I need from Specright and

move on with my project.”

Laura Berlanga

Product Innovation & Research Manager, Ocean Mist Farms

“Being able to review specs

with sales data is changing

the way we do business.”

Molly Fiedler

Chief Innovation Officer, Kira Labs

“Having more people access data

allows us to put world class operating procedures in place.”

Kris Corbin

Chief Supply Chain Officer, Bright Future Foods

Colgate-Palmolive: Increasing Collaborating and Reducing Machinery Start Up Time

Colgate-Palmolive supplies products to more than 200 countries and has over 40 manufacturing facilities; each with their own team of engineers. Without a unified source of data, engineers had no visibility into what other facilities were doing. Learn how Colgate-Palmolive used Specright to increase visibility, test and deploy machines faster, and speed up large projects.

Discover the Impact

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.